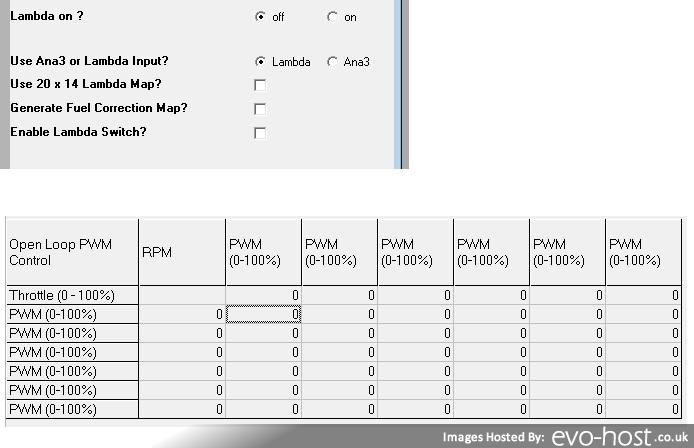

However, wideband closed loop control is either off or on, as chosen either in software or switch. You cannot change this by rpm or any other parameter, same as the S series is today.

Only narrowband can be turned off and on as you describe ( unless things have changed )

For the boost map. The PWM's vs TPS are there to give some resolution to power delivery via your throttle. So 100% TPS will provide max desired boost pressure. But you can also configure it so at say 50%, it may only achieve half of your max boost pressure, as it isnt always easy to modulate this using your foot.

Or if an engine spools very very early at say only 20-30% throttle, it may try and hit max boost far too early. It's entirely up to you and your engine package how these are configured.

Easiest is to fill entire map with same value until at WOT you have your desired boost target achieved thgroughout the rpm range. Then scale back the lower TPS numbers. Starting from zero of course, and working up to your desired boost pressure.

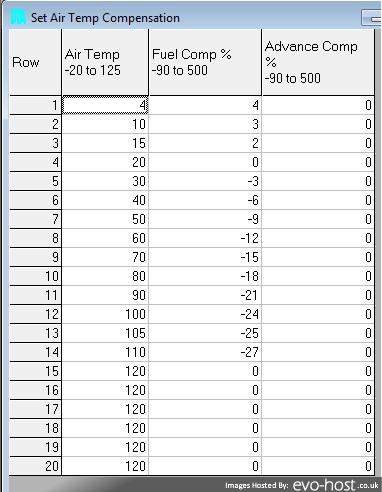

While these scalings may be sound for a n/a car with a sensor placed never to see heat soak and are theoretically correct...

I would never used them on a boosted car. I would be inclined to leave temps over say 30degC at zero. Perhaps even making them richer from say 50degC upwards.

The last thing you want is a boosted engine pulling more fuel whilst on boost.

It will also hep your heat issue. There is no need to be pulling such large amounts if fuel at those temperatures IMO. And is exactly why you're seeing lean mixtures.

Although it's largely because it is a false air temp reading.